Projects

Why Welding and Fabrication Skills Are Essential for Modern Industries

In the rapidly evolving landscape of modern industries, the significance of welding and fabrication skills has become more pronounced than ever. According to the American Welding Society, the demand for skilled welders is projected to grow by 26% from 2020 to 2030, highlighting the pivotal role this profession plays in meeting the needs of various sectors, including construction, manufacturing, and energy. Welding and fabrication not only contribute to the quality and safety of the products but also ensure efficiency in the production processes, underscoring their importance in maintaining competitive advantage.

Moreover, the Global Welding Equipment Market was valued at approximately $19.6 billion in 2022 and is expected to grow at a steady rate, reflecting the increasing reliance on these skills. As industries strive to innovate and improve production capabilities, the mastery of welding and fabrication techniques equips workers with the necessary tools to adapt to new technologies and methodologies. The integration of automation and digitalization in welding processes further amplifies the demand for professionals who are both skilled and versatile in their approach, making welding and fabrication an essential foundation for the workforce of today and tomorrow.

Importance of Welding Skills in the Manufacturing Sector

Welding skills play a vital role in the manufacturing sector, serving as a foundational element for creating reliable and durable products. As manufacturing techniques evolve, skilled welders are increasingly sought after to ensure precision and quality in the assembly of various components. From automotive manufacturing to aerospace applications, welding techniques are employed to fuse materials together, creating structures that meet stringent safety and performance standards. Without proficient welders, the integrity of products could be compromised, leading to potential failures and significant financial losses for companies.

Moreover, with the rise of advanced manufacturing technologies, the complexity of welding tasks has increased. Manufacturers are adopting new materials and innovative designs, requiring welders to possess not only basic skills but also specialized training and adaptability. This need for advanced welding skills enhances the workforce's capabilities, allowing companies to stay competitive in a global market. As industries continue to innovate, the demand for skilled welding professionals will likely grow, making these skills essential for the sustainability and advancement of the manufacturing sector.

Impact of Fabrication Techniques on Product Quality

The quality of products in modern industries largely hinges on the fabrication techniques employed during the manufacturing process. Effective welding and fabrication skills are crucial in ensuring that the final products meet both aesthetic and functional standards. High-quality welds not only improve the structural integrity of components but also enhance their durability, reducing the likelihood of failures or defects over time. For industries such as automotive, aerospace, and construction, where safety and reliability are paramount, the consequences of poor fabrication can be severe.

Moreover, advanced fabrication techniques enable the customization of products to meet specific customer needs while maintaining high-quality standards. Techniques such as precision welding and automated fabrication provide consistency and repeatability in production, leading to reduced variability in product quality.

As industries continue to evolve with emerging technologies, the integration of innovative fabrication methods will be essential in meeting the growing demands for high-performance and sustainable products. The synergy between skilled fabrication workers and modern technology will shape the future landscape of production quality, making these skills indispensable in today's competitive market.

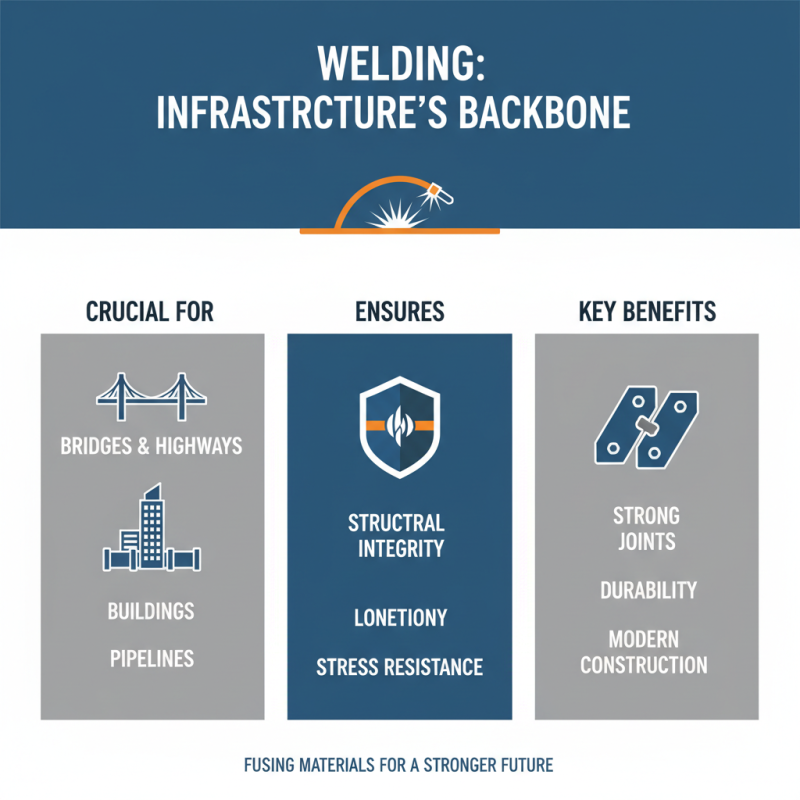

Role of Welding in Infrastructure Development and Maintenance

Welding plays a crucial role in the development and maintenance of infrastructure, serving as the backbone of various construction projects. From bridges and highways to buildings and pipelines, welding is essential in ensuring structural integrity and longevity. The ability to fuse materials together creates strong joints that can withstand significant stress and environmental factors, making it indispensable for modern construction.

One key tip for those involved in welding and fabrication is to prioritize safety at all times. Wearing appropriate protective gear, maintaining a well-ventilated workspace, and ensuring that all equipment is in good condition are critical steps to prevent accidents. Additionally, continuous education on the latest welding techniques and technologies is vital, as it enhances skill levels and improves job site efficiency.

Maintenance of welded structures is equally important. Regular inspections can help identify potential weaknesses before they lead to costly repairs or safety hazards. It's advisable to implement a routine maintenance schedule that includes checking for cracks, corrosion, and misalignment. By staying proactive, industries can extend the lifespan of their infrastructure and ensure safe and reliable facilities for the public.

Advancements in Welding Technology for Modern Applications

Advancements in welding technology have significantly transformed modern industries, enabling enhanced productivity and efficiency across various sectors. According to a report by the American Welding Society, the welding market is projected to reach over $30 billion by 2025, fueled by innovations in processes and materials. Technologies such as automated welding systems, laser welding, and robotic welding have emerged to meet the growing demand for precision and speed. These advancements allow manufacturers to achieve higher production rates while maintaining quality, which is crucial in competitive markets.

Furthermore, the integration of digital tools in welding, such as smart sensors and AI-driven analytics, has revolutionized the monitoring and control of welding processes. A report from MarketsandMarkets highlights that the use of smart welding systems can improve operational efficiency by up to 25%, significantly reducing downtime and wastage. This shift not only supports more sustainable practices but also ensures that skilled welders are equipped with cutting-edge tools that enhance their work and adaptability in a rapidly evolving industrial landscape. As industries continue to embrace these technological advancements, the demand for skilled professionals who can navigate and utilize these modern welding techniques will remain essential.

Career Opportunities in Welding and Fabrication Industries

The welding and fabrication industries are experiencing unprecedented growth, presenting numerous career opportunities for skilled workers. According to the U.S. Bureau of Labor Statistics, employment of welders, cutters, solderers, and brazers is projected to grow by 3% from 2021 to 2031, reflecting the ongoing demand for skilled trade professionals across various sectors, including construction, manufacturing, and automotive industries. As industries increasingly recognize the value of precision welding and fabrication, the need for qualified workers will only intensify, resulting in a plethora of job openings.

In addition to traditional roles, advancements in technology are creating new career paths within welding and fabrication. Positions such as robotic welding technicians and fabrication specialists are emerging, reflecting the industry's shift towards automation and high-tech solutions. A report from the American Welding Society estimates that the welding industry will require 200,000 new workers annually to keep pace with demand, highlighting the expansive career potential available. This demand not only covers entry-level positions but also opens avenues for advanced careers in supervision, management, and technical sales, making welding and fabrication a viable option for those seeking a rewarding and stable career path.

Career Opportunities in Welding and Fabrication Industries

Related Posts

-

How to Master Welding and Fabrication Techniques for Successful Projects

-

10 Essential Tips for Successful Online Fabrication Projects

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget

-

Top 10 Tips for Successful Online Sheet Metal Fabrication Projects

-

Top 10 Custom Stainless Fabrication Techniques for Your Next Project

-

How to Get Started with Welding and Fabrication Techniques for Beginners