Projects

What is Tube Fabrication and How Does it Impact Manufacturing Processes

Tube fabrication is a pivotal aspect of modern manufacturing processes, playing a crucial role in various industries such as automotive, aerospace, and construction. As technology advances, the methods and machinery involved in tube fabrication continue to evolve, leading to enhanced efficiency and precision. Industry expert Dr. Emily Johnson, a leading figure in the field of mechanical engineering, emphasizes the significance of this process by stating, "Tube fabrication is not just about shaping metal; it's about innovating manufacturing solutions that drive industry forward."

The impact of tube fabrication on manufacturing is profound. It allows for the creation of complex geometries and designs that are essential for modern applications. Furthermore, advancements in tube fabrication techniques, such as laser cutting and robotic welding, contribute to reduced production times and minimized waste, thus promoting sustainability. As Dr. Johnson aptly points out, the focus on efficient tube fabrication processes is what differentiates successful manufacturers from the rest in today's competitive landscape.

Understanding the intricacies of tube fabrication is essential for manufacturers aiming to stay ahead. By investing in state-of-the-art tube fabrication technologies and techniques, companies can enhance their production capabilities, ensure product quality, and respond effectively to market demands. In this exploration of tube fabrication, we will delve into its definition, the methodologies involved, and its transformative impact on the broader manufacturing landscape.

Definition of Tube Fabrication in Manufacturing

Tube fabrication is a critical process in the manufacturing industry that involves the shaping and assembly of tubular structures for various applications. This technique encompasses a variety of processes, including cutting, bending, and welding, tailored to meet specific design requirements. According to the Fabricators and Manufacturers Association, approximately 25% of the fabricated metal products industry is dedicated to tube fabrication, indicating its significant role in overall manufacturing. With its wide range of applications in sectors such as automotive, aerospace, and construction, tube fabrication is essential for creating components that require both strength and lightweight characteristics.

In terms of economic impact, the tube fabrication market is projected to grow significantly, with a report from Grand View Research anticipating a compound annual growth rate (CAGR) of 5.6% from 2021 to 2028. This growth is driven by advancements in technology, such as automated tube cutting and robotic welding, which enhance precision and efficiency in manufacturing processes. Additionally, the demand for custom and complex designs continues to rise as industries seek to improve performance and reduce weight in their products. As a result, tube fabrication not only enhances the functionality of various components but also contributes to the overall efficiency and sustainability of modern manufacturing operations.

Impact of Tube Fabrication on Manufacturing Processes

Key Techniques and Processes in Tube Fabrication

Tube fabrication involves a series of specialized techniques and processes that convert raw tubing material into precise shapes and structures for various applications. One of the key techniques in tube fabrication is bending, which allows manufacturers to create curves and angles in the tubing without compromising its integrity. This process utilizes various tools such as mandrel benders or induction benders, enabling the production of complex components for industries like automotive and aerospace where space and aerodynamics are critical.

Another essential process in tube fabrication is welding. This technique is used to join multiple tube sections or connect tubes to other components, ensuring a strong and durable assembly. Advanced methods such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding allow for precise control over the heat and materials involved, leading to high-quality joints that can withstand significant stress. Additionally, the implementation of quality control measures throughout the fabrication process ensures that the final products meet strict industry standards, thus enhancing reliability and performance in their intended applications.

Materials Commonly Used in Tube Fabrication

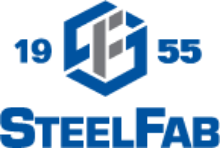

Tube fabrication is a critical process in various manufacturing sectors, involving the shaping and assembly of tubes to create complex structures. The selection of materials for tube fabrication plays a significant role in determining the quality, durability, and effectiveness of the final product. Commonly used materials include metals like steel and aluminum due to their strength and versatility. Steel, particularly in the forms of stainless steel and carbon steel, is favored for its durability and resistance to corrosion, making it ideal for applications in construction, automotive, and aerospace industries.

In addition to steel, aluminum is increasingly popular in tube fabrication for its lightweight properties and excellent resistance to oxidation. This makes aluminum tubes suitable for industries where weight reduction is critical, such as in transportation and manufacturing of lightweight consumer products. Another material worth mentioning is plastic, which is used for specific applications where corrosion resistance and low weight are essential. Plastic tubes can be found in industries ranging from chemical processing to plumbing, illustrating the diverse applications of tube fabrication across various sectors. The choice of material ultimately influences the tube's performance, reliability, and cost-effectiveness in its intended use.

Impact of Tube Fabrication on Product Quality and Efficiency

Tube fabrication plays a crucial role in enhancing product quality and operational efficiency across various manufacturing sectors. According to a recent report by the Fabricators & Manufacturers Association, tube fabrication processes can reduce production time by up to 30% compared to traditional methods. This increase in efficiency is largely due to the use of advanced technologies such as CNC machining and laser cutting, which not only streamline operations but also minimize material waste. The precision achieved through these technologies ensures that products are manufactured to exact specifications, thus improving overall quality and consistency.

Moreover, the impact of tube fabrication extends beyond mere efficiency. A study published in the Journal of Manufacturing Processes indicates that companies employing high-quality tube fabrication techniques experience a 25% reduction in product defects. This is particularly significant in industries such as automotive and aerospace, where safety and reliability are paramount. By adopting precise fabrication methods, manufacturers can enhance the durability and performance of their products, leading to higher customer satisfaction and reduced warranty claims. The synergy between efficient fabrication and high standards of quality ultimately supports a more sustainable manufacturing ecosystem.

What is Tube Fabrication and How Does it Impact Manufacturing Processes - Impact of Tube Fabrication on Product Quality and Efficiency

| Dimension | Impact on Product Quality | Impact on Efficiency |

|---|---|---|

| Material Selection | Improves durability and performance characteristics. | Reduces waste and cost of materials. |

| Fabrication Technology | Enhances precision and consistency. | Speeds up production times and lowers labor costs. |

| Quality Control Measures | Ensures compliance with industry standards. | Reduces rework and scrap rates. |

| Design Optimization | Allows for innovative designs that enhance functionality. | Improves efficiency by reducing material use. |

| Post-Fabrication Treatment | Increases resistance to corrosion and wear. | Extends product lifespan and reduces maintenance costs. |

Future Trends in Tube Fabrication Technology and Applications

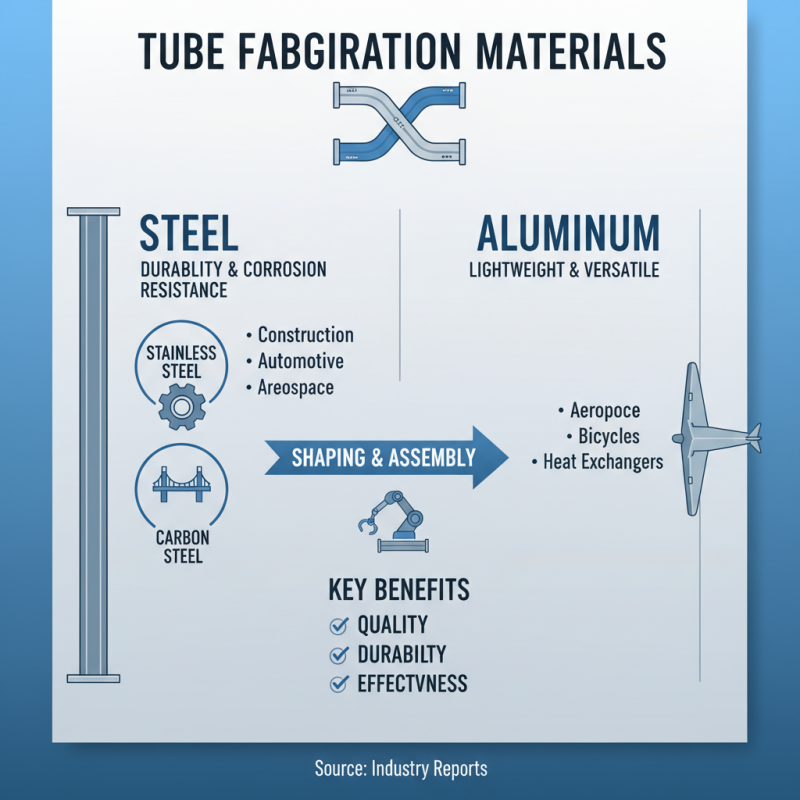

The field of tube fabrication is witnessing significant advancements that are reshaping manufacturing processes across various industries. One of the most exciting future trends is the integration of automation and robotics, which streamlines operations and enhances precision. Automated systems can handle intricate tube shaping and welding tasks that minimize human error, leading to higher efficiency and reduced production time. Additionally, the adoption of artificial intelligence in monitoring and optimizing fabrication processes is set to transform the industry, allowing for predictive maintenance and real-time adjustments, ultimately improving overall product quality.

Another emerging trend is the increasing use of advanced materials, such as lightweight composites and high-strength alloys, which are meeting the demand for more efficient and durable products. This shift not only enhances the performance of fabricated tubes but also contributes to sustainability by reducing weight and material waste during manufacturing. As industries strive for eco-friendly solutions, materials that enhance energy efficiency while maintaining structural integrity are becoming paramount.

Tip: When considering tube fabrication technologies, it's beneficial to stay updated with industry innovations, as adopting new technologies can lead to significant efficiency gains. Additionally, collaborating with skilled engineers who understand the latest trends can provide a competitive edge in optimizing fabrication processes for your specific needs.

Related Posts

-

10 Best Tube Fabrication Techniques for Optimal Performance

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget

-

How to Get Started with Welding and Fabrication Techniques for Beginners

-

Top 10 Important Factors to Consider in Iron Fabrication Projects

-

Top 10 Custom Stainless Fabrication Techniques for Your Next Project

-

2025 Top Steel Beam Fabrication Techniques for Modern Construction