Projects

2026 Top Trends in Custom Metal Fabrication You Need to Know

Custom metal fabrication continues to evolve, shaping various industries. Experts highlight significant trends for 2026 that every professional should consider. John Smith, a leading figure in custom metal fabrication, notes, “Innovation drives our industry forward, but we must adapt or get left behind.”

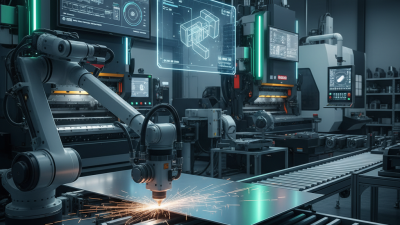

With technological advancements, automation is becoming crucial in custom metal fabrication processes. Automated machinery enhances precision and efficiency, reducing labor costs. Yet, some companies struggle to keep pace with these changes, risking obsolescence.

Sustainability is another key trend. Consumers increasingly demand eco-friendly practices in manufacturing. Custom metal fabrication can leverage this shift by utilizing recyclable materials. However, not all businesses have embraced these sustainable practices. They need to reevaluate their methodologies to remain competitive. Embracing these trends is not just optional; it is essential for survival in the evolving landscape of custom metal fabrication.

Emerging Technologies in Custom Metal Fabrication for 2026

As we look toward 2026, the custom metal fabrication industry is set to be heavily influenced by emerging technologies. According to recent industry reports, automation and robotics are transforming traditional methods. It is projected that over 50% of metal fabrication processes will adopt automated systems, enhancing efficiency and reducing labor costs. However, this shift raises concerns about workforce displacement and the need for skilled training programs.

Another significant area is the integration of additive manufacturing. This technology allows for complex designs that were once impossible with conventional techniques. Research indicates that the market for metal 3D printing will reach $6.5 billion by 2026. But challenges remain, including material limitations and the long production times associated with high-quality prints. As manufacturers explore this option, they must weigh the benefits against these potential drawbacks.

Sustainability is also at the forefront of innovations. A study shows that 70% of companies are investing in eco-friendly practices. Recycled materials and energy-efficient processes are becoming standard. Yet, the question persists: How effective will these measures be in the long run? Balancing cost with environmental impact is a challenge that will require ongoing attention.

Sustainable Practices and Materials in Metal Fabrication

In recent years, the metal fabrication industry has seen a notable shift towards sustainable practices. More companies are incorporating recycled materials into their projects. This reduces waste and brings a new life to old metals. For example, using reclaimed steel can significantly lower carbon footprints. Innovations in this area are often impressed alongside environmental goals.

Another significant trend is the use of eco-friendly coatings and finishes. These materials are increasingly safer for both the environment and human health. Traditional paints contain harmful solvents, while newer options use water-based formulas. However, these new materials sometimes lack the durability of their predecessors. It’s essential for manufacturers to find a balance between sustainability and product longevity.

Companies are also exploring energy-efficient processes. Techniques like laser cutting and advanced welding can save energy. Yet, these methods often require high initial investments and training. Smaller businesses may struggle to adopt these technologies. It's a complex challenge in an industry where tradition often takes precedence.

Automation Trends Reshaping the Metal Fabrication Industry

The metal fabrication industry is witnessing a significant transformation due to automation. Recent reports suggest that automation can increase efficiency by 30% in manufacturing processes. This reduction in manual labor not only streamlines operations but also minimizes human error. Companies adopting automated systems are producing high-quality products at a lower cost.

Robotics are becoming integral to metal fabrication. Advanced robots can perform complex welding tasks while ensuring precision. They increase safety by handling hazardous materials. Interestingly, around 60% of fabricators noted a push toward adopting these technologies. However, the transition can be challenging. Workers may feel threatened by robots. There’s a need for training to help them adapt to new roles.

Despite the benefits, some areas remain untapped. Data shows that many small businesses still resist automation. Concerns about high initial costs and lack of technical skills persist. These issues highlight a gap that needs addressing. Understanding automation requires a cultural shift within organizations. The future of metal fabrication hinges on overcoming these barriers. Embracing automation is essential, but the journey will not be easy.

Customization and Personalization in Metal Fabrication Solutions

Customization and personalization are reshaping the metal fabrication industry. Companies seek to meet diverse customer needs. According to recent market data, 70% of consumers prefer products tailored to their specifications. This shifts the focus towards bespoke solutions in metal fabrication.

Many businesses still struggle to implement effective customization strategies. Some may overlook the importance of accurate design specifications. Communication gaps can lead to inefficiencies. Investing in robust design software can significantly enhance the customization process.

Tip: Consider integrating 3D modeling. This technology allows for precise visualizations of customized designs before production. Moreover, receiving customer feedback early in the design phase can refine the final product. As trends evolve, adaptability is key. Emphasizing personalization fosters deeper customer relationships, driving loyalty and long-term success in the competitive landscape.

Market Demands and Consumer Preferences Shaping Metal Fabrication

The landscape of metal fabrication is evolving. Market demands are shifting rapidly. Consumers increasingly seek customization and sustainability. The focus is on how materials can be tailored to meet specific needs. This trend is evident in various sectors, from automotive to construction.

Tips: Always listen to customer feedback. Their preferences can guide your designs. Adjustments may help you stay competitive.

The rise of eco-friendly materials also shapes the market. Many consumers prefer options that minimize environmental impact. This challenge requires fabricators to innovate constantly. Traditional methods may not suffice; new techniques must be explored. There’s a growing need for education on sustainable practices within the industry.

Tips: Conduct regular training for your team. Knowledge in green technologies can enhance your offerings. Keep experimenting with materials and processes as consumer preferences evolve.

2026 Top Trends in Custom Metal Fabrication

This chart illustrates the anticipated trends in custom metal fabrication for 2026, focusing on market demands and consumer preferences. Key areas of growth include Advanced Welding Techniques, Automation and Robotics, Eco-friendly Materials, Customization Options, and Smart Manufacturing.

Related Posts

-

2025 Top Trends in Precision Sheet Metal Fabrication You Need to Know

-

Top 5 Online Steel Fabrication Services You Need to Know in 2023

-

Top 10 Tips for Successful Online Sheet Metal Fabrication Projects

-

What is Stainless Fabrication Its Process Benefits and Applications

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget

-

10 Best Tube Fabrication Techniques for Optimal Performance