Projects

Top 10 Custom Stainless Fabrication Techniques for Your Next Project

In the world of manufacturing, "custom stainless fabrication" has emerged as a crucial process that allows for the creation of tailored components suited to specific project needs. Industry expert Mark Thompson, a seasoned engineer with over 15 years of experience in metal fabrication, emphasizes the significance of precision in this domain, stating, "The success of any project relies heavily on the accuracy and quality of the custom stainless fabrication techniques employed."

This statement resonates in an industry where adaptability and innovation are paramount. As businesses strive to meet unique demands, understanding various fabrication techniques can significantly enhance efficiency and quality. Whether it's laser cutting, welding, or forming, each method plays a vital role in shaping the final product. As we delve into the top ten custom stainless fabrication techniques, we'll explore how these practices not only elevate project outcomes but also contribute to a more sustainable and resource-efficient manufacturing environment.

Overview of Custom Stainless Fabrication Techniques

Custom stainless fabrication techniques play a pivotal role in a wide range of industries, allowing for tailored solutions that meet specific project requirements. One of the most common techniques is welding, which joins two stainless steel parts together through various methods such as MIG or TIG welding. This process not only ensures structural integrity but also allows for intricate designs that can enhance the overall aesthetics and functionality of the fabricated piece. Additionally, laser cutting technology stands out as it offers precision and clean edges, making it ideal for complex shapes and designs that require a high level of accuracy.

Another notable fabrication technique is machining, which involves shaping stainless steel components using processes like milling or turning. This method provides versatility, allowing for high tolerances and smooth finishes that are often necessary in industries like aerospace and automotive. Alongside machining, bending techniques further expand the design possibilities, enabling the creation of components with various angles and curves, crucial for both functional and decorative applications. Each of these techniques contributes significantly to the effective use of stainless steel in projects, ensuring durability and long-lasting performance.

Cutting Methods: Techniques for Precision and Efficiency

When embarking on a custom stainless fabrication project, the choice of cutting method can significantly impact both precision and efficiency. Techniques such as laser cutting, water jet cutting, and plasma cutting each offer unique advantages, catering to different project requirements. Laser cutting stands out for its ability to create intricate designs with minimal material waste, making it ideal for highly detailed work. Conversely, water jet cutting is known for its versatility and effectiveness on thicker materials, preserving the integrity of the metal without introducing heat distortion. Plasma cutting, while slightly less precise, shines in speed and is suitable for cutting through thicker stainless steel quickly.

**Tips: When selecting your cutting method, consider the thickness and type of stainless steel you are working with, as well as the desired finish quality. For intricate designs, prioritize methods like laser cutting to ensure precision. Additionally, maintaining proper machine calibration is essential to avoid errors and ensure consistent results.**

Another critical factor in achieving optimal results is the preparation of your materials. Properly cleaning and preparing your stainless steel before cutting can minimize slag and improve cut quality. Furthermore, employing the right coolant or cutting fluids can enhance the lifespan of your cutting tools and produce cleaner edges.

**Tips: Always take the time to evaluate your workspace for safety and efficiency. Ensure good lighting and ventilation, and organize tools and materials to streamline the cutting process, which can significantly reduce downtime and enhance productivity.**

Top 10 Custom Stainless Fabrication Techniques for Your Next Project - Cutting Methods: Techniques for Precision and Efficiency

| Technique | Description | Advantages | Typical Applications |

|---|---|---|---|

| Laser Cutting | Utilizes a focused laser beam to cut through stainless steel. | High precision, minimal heat-affected zone. | Signage, intricate designs. |

| Waterjet Cutting | Employs high-pressure water mixed with abrasive materials. | No heat distortion, cuts thick materials. | Aerospace, automotive components. |

| Plasma Cutting | Uses a plasma torch to melt and cut through materials. | Fast cutting speed, effective on thicker materials. | Sheet metal fabrication, automotive repair. |

| Flame Cutting | Involves using a flame to cut through stainless steel. | Cost-effective for thick materials. | Heavy industrial applications, steel components. |

| Shearing | Mechanical process to cut stainless steel sheets. | Good for straight cuts, fast execution. | Metal enclosures, brackets. |

| Die Cutting | Utilizes die tools to create specific shapes from sheets. | High repeatability, minimal waste. | Production of small parts, gaskets. |

| Bending | Alters the stainless steel's shape without cutting. | Versatile, can create complex shapes. | Structural components, frames. |

| Etching | Uses chemicals to remove layers from the material surface. | High detail, precise patterns. | Decorative designs, labels. |

| CNC Machining | Computer-controlled cutting tool that shapes stainless steel. | High accuracy, replicable designs. | Custom parts, prototypes. |

Welding Techniques: Ensuring Strong and Durable Joints

Welding techniques play a crucial role in custom stainless fabrication, ensuring that the joints formed are not only strong but also durable. According to the American Welding Society, improper welding practices can lead to joint failure, resulting in significant financial losses and safety hazards. The choice of welding method, be it TIG, MIG, or stick welding, can significantly impact the overall integrity of the structure being fabricated. For instance, TIG welding is highly regarded for its precision and ability to create clean, strong joints, making it ideal for projects requiring aesthetic appeal alongside structural strength.

Moreover, the American Institute of Steel Construction emphasizes the importance of weld quality assessments, estimating that flawed welds can compromise structural resilience by approximately 30%. Techniques such as preheating the materials and using filler metals that match the base metal composition can greatly enhance the durability of the welds. Additionally, employing non-destructive testing methods—such as ultrasonic testing or radiography—can ensure that the welded joints meet the required standards before the product goes to use. These proactive measures not only aid in compliance with industry specifications but also extend the lifespan of the fabricated stainless structures, thereby providing a reliable solution for demanding projects.

Finishing Processes: Achieving Desired Surface Qualities

Finishing processes play a crucial role in custom stainless fabrication, as they directly impact the aesthetic and functional characteristics of the final product. Achieving the desired surface quality involves a range of techniques tailored to the specific requirements of each project. Surface finishes can enhance corrosion resistance, reduce friction, and improve the overall appearance.

Common methods employed in stainless steel fabrication include grinding, polishing, bead blasting, and electropolishing, each offering unique benefits that cater to different applications.

Grinding is a widely used technique for removing material and creating a smooth surface; it’s effective for achieving tight tolerances and preparing surfaces for further finishing.

Polishing, on the other hand, is ideal for achieving a mirror-like finish, making it a popular choice for products where aesthetics are critical.

Bead blasting provides a more uniform surface texture, which not only adds to the visual appeal but can also enhance adhesion for coatings and other treatments.

Electropolishing involves an electrochemical process that not only improves surface finish but also enhances corrosion resistance by removing a thin layer of material from the surface, resulting in a cleaner and more reflective finish.

By carefully selecting and applying these finishing processes, fabricators can ensure that their stainless steel projects meet both functional requirements and desired aesthetic qualities.

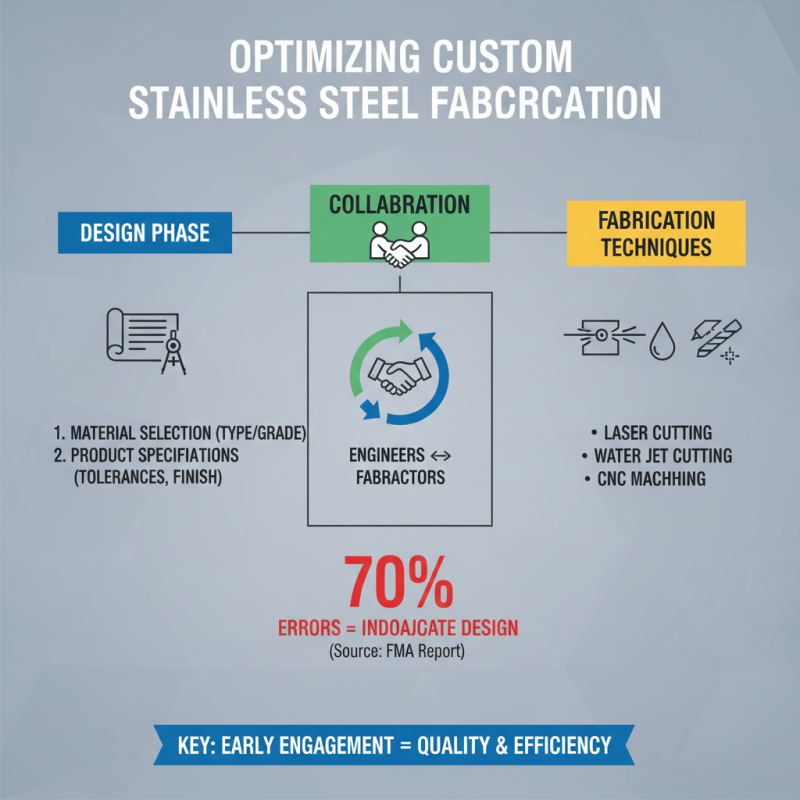

Design Considerations: Tailoring Fabrication to Your Project Needs

When approaching custom stainless fabrication, understanding the design considerations is crucial to tailor the process to your project needs. The principles of effective fabrication hinge not only on the type of stainless steel used but also on the specifications required for the end product. According to a recent industry report by the Fabricators & Manufacturers Association (FMA), nearly 70% of fabrication errors stem from inadequate design processes, highlighting the importance of collaboration between engineers and fabricators during the initial phase. Early engagement allows for the exploration of various techniques such as laser cutting, water jet cutting, or CNC machining, which can be optimized for specific tolerances and finish quality.

Moreover, integrating advanced technology into the design phase can significantly enhance efficiency and accuracy. As per a report from the American Welding Society (AWS), integrating design software with fabrication tools increases production speed by up to 30%, while also reducing material waste. This can be particularly beneficial for projects that require tight timelines and exceptional precision. By focusing on these design considerations—such as material selection, structural integrity, and finish requirements—fabricators can ensure that the final product not only meets but exceeds client expectations, paving the way for innovative applications in various industries.

Related Posts

-

What is Stainless Fabrication Its Process Benefits and Applications

-

10 Best Tube Fabrication Techniques for Optimal Performance

-

Top 10 Important Factors to Consider in Iron Fabrication Projects

-

Top 5 Online Steel Fabrication Services You Need to Know in 2023

-

Top 10 Tips for Successful Online Sheet Metal Fabrication Projects

-

How to Master Welding and Fabrication Techniques for Successful Projects