Projects

How to Choose Custom Sheet Metal Fabrication for Your Project?

Choosing the right custom sheet metal fabrication service can significantly affect your project’s success. Jack Thompson, a seasoned expert in the industry, once stated, “Quality fabrication is the backbone of any custom project.” His words resonate deeply within the community. Many businesses overlook the importance of selecting the right provider.

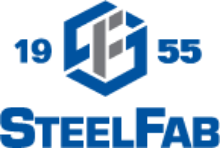

When considering custom sheet metal fabrication, focus on materials, processes, and capabilities. The quality of materials needs assessment. A fabrication shop may boast advanced machines but lacks skilled labor. That is a point to ponder. Additionally, examine their previous projects. Photos can be misleading. Ask for physical samples to ensure they meet your standards.

Common pitfalls occur when clients rush the decision. This haste often leads to frustrations later. A cheaper option may sound appealing but can cause more issues in the long run. Invest the time to evaluate your choices. After all, you want a smooth fabrication process that aligns with your vision.

Understanding Your Project Requirements for Custom Sheet Metal Fabrication

Understanding your project requirements is crucial for effective custom sheet metal fabrication. Begin by assessing the purpose of your fabrication. Are you aiming for parts for machinery, or components for consumer products? This determination will guide your choice in materials and production techniques. The sheet metal fabrication market is expected to grow significantly, valued at over $229 billion by 2027, indicating a robust demand for tailored solutions.

Think about the specific dimensions and tolerances needed for your project. Even minor discrepancies can lead to major operational issues. According to industry reports, nearly 30% of projects experience setbacks due to improper specifications. Engaging with engineers or fabrication experts early in the design phase can prevent costly mistakes. Consider using CAD software for precise modeling, as 75% of successful fabricators rely on this technology to streamline their process.

Evaluate the environmental impact of your materials and production methods. Sustainability is becoming a priority, with 40% of manufacturers exploring eco-friendly options. Selecting recyclable materials is not just beneficial for the planet; it can also resonate well with consumers. Balance aesthetics, cost, and functionality to avoid compromising your project. Each decision made should reflect the overall vision while maintaining feasibility.

Evaluating Different Materials for Sheet Metal Fabrication

Choosing the right materials for custom sheet metal fabrication is essential. The material can greatly influence the durability and functionality of the final product. Steel is a common choice. It's strong and versatile. However, it can be heavy and prone to rust without proper coating. Aluminum, on the other hand, is lightweight and resistant to corrosion. It’s great for projects requiring a lightweight solution.

Copper and brass offer unique benefits as well. They have excellent thermal conductivity. They are often used in electrical components. But their cost can be significant, making them less ideal for larger projects. Consider these factors carefully. Cost vs. durability is a common dilemma.

Reflect on your project's specific needs. Different materials can lead to unexpected challenges. Some may not perform well in extreme conditions. Others might need additional treatments. Always consult with experts. Their insights can reveal crucial details. The right choice will enhance your project and prevent future issues.

Selecting the Right Fabrication Techniques for Your Needs

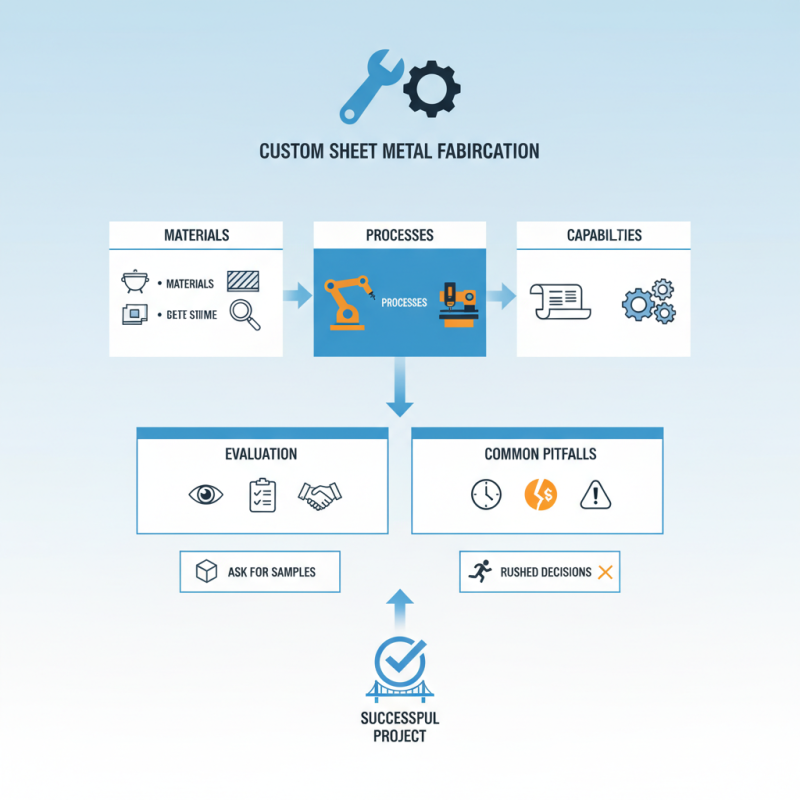

Choosing the right fabrication techniques for your project is crucial. Different methods can significantly impact the design and functionality of your product. Various factors come into play, such as material type, thickness, and intended use. Consider what aspects matter most to you.

Tip: Identify the primary purpose of your sheet metal. This decision shapes the entire process. Will it be structural, aesthetic, or both? Understanding this allows you to focus on the right techniques.

Laser cutting, for instance, is precise. It suits detailed designs but may not be cost-effective for larger runs. On the other hand, stamping is efficient for mass production but offers less customization. Reflecting on your needs is essential here.

Tip: Always consider the long-term implications of your choices. A good technique today may not hold up in the future. Think about maintenance, durability, and potential design evolution over time. This foresight can save resources and stress later.

Assessing Manufacturer Capabilities and Expertise

Choosing the right custom sheet metal fabrication partner is crucial. Assessing a manufacturer's capabilities and expertise can impact your project's success significantly. A report by the Fabricators and Manufacturers Association notes that 50% of projects fail due to inadequate provider qualifications. Therefore, understanding the manufacturing processes is vital.

Explore the manufacturer's equipment and technology. Are they using CNC machines? What about laser cutting? The level of automation can affect efficiency and accuracy. Advanced technologies can lead to better tolerances, which are essential in industries like aerospace. A recent industry study highlighted that companies using the latest technology saw a 30% increase in production efficiency over those relying on outdated methods.

Quality control is another key factor. Manufacturers should have robust quality assurance measures in place. Look for certifications, such as ISO 9001. They reflect commitment to quality. A common oversight is skipping this due diligence. Poor quality can lead to costly rework or project delays. Additionally, seek testimonials or case studies. Real-world examples will offer insights into their expertise and reliability. Each detail counts in making an informed choice.

Comparing Costs and Lead Times for Custom Fabrication Services

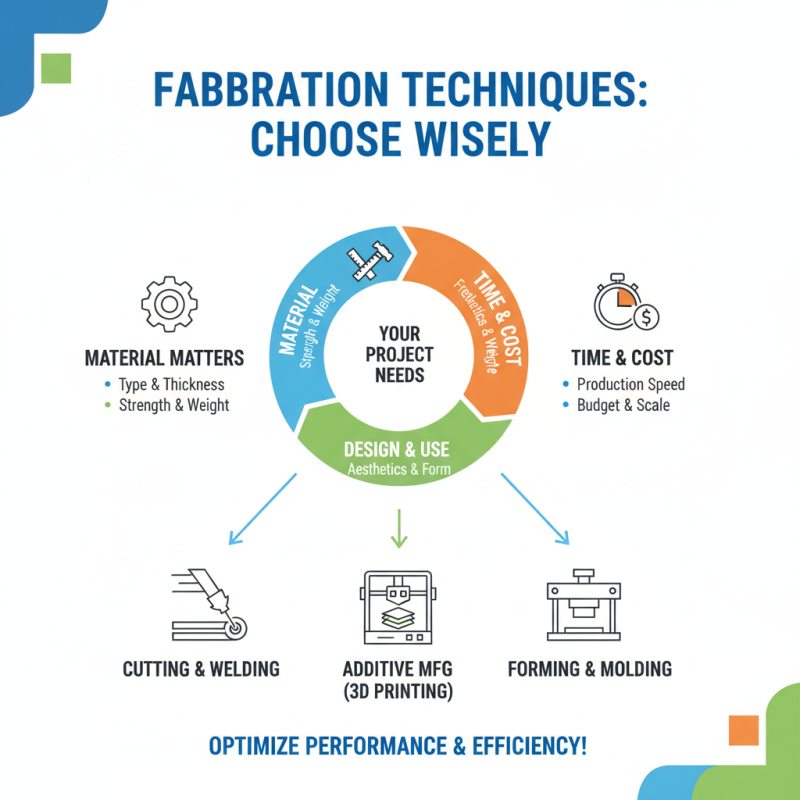

When selecting custom sheet metal fabrication services, comparing costs and lead times is critical. Fabrication methods greatly affect your budget. Laser cutting, for example, may be costlier than traditional methods. However, the precision it offers can reduce waste. Make sure to ask potential fabricators about their pricing structures. Understanding how they calculate costs can help identify hidden fees.

Lead times can be just as important. Some companies may promise quick turnarounds but might sacrifice quality. A two-week completion time might sound appealing, but check what compromises may occur. In contrast, a company that takes four weeks might produce superior work. Always clarify timelines upfront. This can prevent costly delays later on.

Consider the balance between cost and quality. A low bid may seem attractive. Yet, it often leads to poor craftsmanship. Likewise, a high price does not guarantee the best outcome. You're looking for a well-rounded solution. Take your time, research, and ask questions. Ask for references and past work samples. The right choice can significantly impact your project's success.

Related Posts

-

Top Custom Steel Fabrication Trends to Watch in 2025: What You Need to Know

-

Top 10 Benefits of Bespoke Metal Fabrication for Your Projects?

-

How to Master Welding and Fabrication Techniques for Successful Projects

-

How to Get Started with Welding and Fabrication Techniques for Beginners

-

Why Welding and Fabrication Skills Are Essential for Modern Industries

-

2026 Top Trends in Custom Metal Fabrication You Need to Know