Projects

Top Tips for China Sheet Metal Fabrication Success?

China sheet metal fabrication is a rapidly evolving industry. It offers immense potential for businesses hoping to reduce costs and enhance efficiency. However, success in this sector is not guaranteed. A clear understanding of the market is essential.

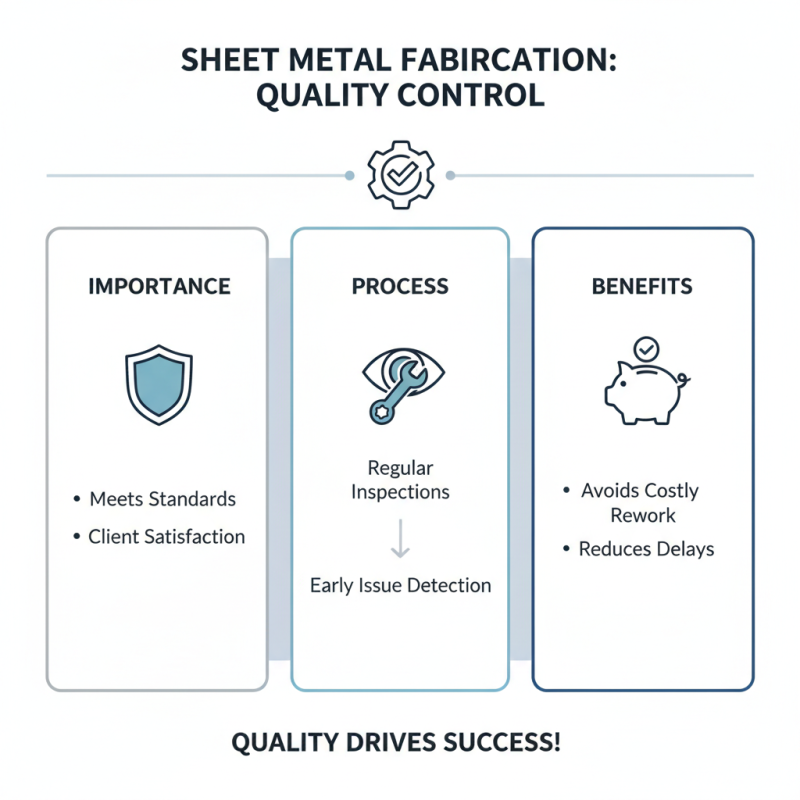

Quality control can sometimes be overlooked. Yet, it plays a crucial role in fabrication. Poor quality can lead to product failures and financial losses. It’s vital to implement robust inspection processes. Communication with suppliers is another aspect that needs attention. Misunderstandings can result in delays and increased expenses.

Innovation and technology are key to staying competitive. However, not all companies invest in the latest tools. This can hinder their growth. Fostering a culture of continuous improvement is important. Ignoring feedback from clients can also be detrimental. Listening to their needs can drive better outcomes. Embracing these factors ensures a successful journey in china sheet metal fabrication.

Understanding the Basics of Sheet Metal Fabrication in China

Sheet metal fabrication in China has become a crucial industry. Understanding the basics is essential for success. The process involves cutting, bending, and assembling sheets of metal. Each step requires precision and skill. Common materials include aluminum and steel. These metals are favored for their strength and versatility.

Many companies struggle with sourcing materials. Quality can be inconsistent. It is vital to establish reliable suppliers. Communication plays a significant role. Language barriers may lead to misunderstandings. Effective collaboration can alleviate some of these issues, but challenges remain.

Equipment and technology also matter. Investing in modern tools can improve efficiency. Yet, many shops still use outdated machinery. This can slow down production and affect quality. Training workers adequately is another challenge. Skilled labor is in high demand, making it hard to find qualified staff. Continuous improvement is necessary to stay competitive in this dynamic market.

Sheet Metal Fabrication Industry Insights

Essential Materials and Tools for Effective Fabrication

In sheet metal fabrication, choosing the right materials is crucial. Stainless steel and aluminum dominate the industry due to their strength and corrosion resistance. Reports indicate that the global sheet metal fabrication market size was valued at around $19 billion in 2021. This trend emphasizes the need for quality materials that can withstand various operating environments.

Tools also play a vital role in achieving effective fabrication. Laser cutters and press brakes are essential. Studies show that investments in advanced machinery can improve efficiency by 30%. However, many businesses overlook the importance of proper maintenance. Failing to maintain equipment can lead to costly downtime and diminished quality.

While automating processes is beneficial, it can create dependency. Operators must still possess traditional skills to troubleshoot challenges. A blend of modern technology and hands-on expertise can lead to the best results. Engaging in continuous training is often neglected, yet it is vital for sustaining quality and innovation in production.

Key Techniques in Sheet Metal Forming and Cutting

Sheet metal fabrication requires precision and skill. Understanding key techniques in forming and cutting is essential for success. One crucial method is bending. This transforms flat metal sheets into desired angles. A well-designed die can enhance this process. Using the right tooling improves accuracy significantly. However, it’s vital to consider the material's limitations. Not every sheet bends easily. Sometimes, trial and error leads to better solutions.

Cutting is another important aspect. Laser cutting offers high precision. It creates intricate designs with minimal waste. However, managing heat is crucial to avoid warping. Poor control during this process can lead to flaws. Plasma cutting is another option, frequently used for thicker materials. It’s faster but can produce rough edges. Knowing when to choose each method takes experience.

Quality checks are often overlooked. After forming or cutting, those imperfections can go unnoticed. Regular inspections can save time in the long run. It’s important to reflect on past errors. Learning from them can prevent future mistakes and improve overall efficiency. Each project teaches valuable lessons. Embracing these challenges builds expertise in sheet metal fabrication.

Quality Control Measures for Successful Fabrication Projects

Quality control is crucial in the sheet metal fabrication process. It ensures that every project meets standards and satisfies client expectations. Regular inspections can catch issues early. This helps avoid costly rework and delays.

Implementing standardized procedures is a solid tip for improving quality. These procedures ensure consistency across production. Each worker should follow clear guidelines. This reduces the chances of human error. However, it's essential to regularly review these guidelines. Sometimes, they may be outdated or irrelevant.

Another aspect is using the right tools. Investing in quality machinery and equipment can significantly impact the end product. While cost-saving may seem appealing, using inferior tools can lead to defects. It may result in wasted materials and time. Skilled operators are vital, too. Continuous training can elevate their expertise, but not all employers prioritize this.

Navigating Regulatory Standards and Compliance in China

Navigating regulatory standards and compliance in China can be challenging for sheet metal fabrication. Understanding the local laws is crucial. Manufacturers must become familiar with standards set by regulatory bodies. This may involve extensive paperwork and inspections. Compliance can slow down production. However, it is a necessary step for long-term success.

Engaging a reliable local partner can facilitate this process. They can help navigate the complex landscape of regulations. A partner might also provide insights into common pitfalls. Ensuring that all materials and processes adhere to standards is essential. This is where mistakes can happen. A slight deviation from compliance can lead to delays or fines. It’s vital to invest time in training staff on these standards.

Regular audits and updates to processes are also important. Keeping up with changes in regulations can be overwhelming. Some companies may overlook updates and risk non-compliance. This can damage reputation and impact business relationships. Continuous learning and adaptation are key. Taking a proactive approach can make a significant difference in maintaining compliance.

Related Posts

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget

-

Why Welding and Fabrication Skills Are Essential for Modern Industries

-

10 Best Tube Fabrication Techniques for Optimal Performance

-

What is Metal Part Fabrication? Techniques, Processes, and Applications Explained

-

What is Tube Fabrication and How Does it Impact Manufacturing Processes

-

Top 5 Online Steel Fabrication Services You Need to Know in 2023