Projects

Top 10 Benefits of Bespoke Metal Fabrication for Your Projects?

Bespoke metal fabrication is revolutionizing many industries, from construction to automotive. Custom solutions cater to specific project requirements, enhancing efficiency and functionality. According to a recent report by Market Research Future, the bespoke metal fabrication market is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2027. This growth reflects the increasing demand for tailored metal solutions.

Industry expert John Smith emphasizes, "Bespoke metal fabrication allows for unique designs that standard solutions cannot achieve." His insight highlights the value of customization. Custom fabrication not only meets the unique needs of a project but can also lead to significant cost savings. However, it’s essential to understand the challenges involved, such as longer lead times and potential inconsistencies in quality.

While bespoke metal fabrication offers numerous benefits, it requires careful planning and execution. Businesses must weigh these advantages against the need for precision and reliability. Investing in bespoke solutions means committing to a process that, while rewarding, is not without its complexities. There’s always room for improvement, and ongoing feedback can drive further innovations in this dynamic field.

Benefits of Customization in Metal Fabrication for Unique Project Needs

When it comes to metal fabrication, customization plays a key role. Each project has unique requirements, and bespoke solutions can meet these specific needs. Off-the-shelf products often fall short. They may not fit perfectly or deliver the desired performance. Custom metal fabrication allows for tailored dimensions and materials. This ensures each piece integrates seamlessly into your project.

The benefits of this customization approach are significant. Customized solutions can enhance durability and functionality. For example, a uniquely shaped metal part can improve aerodynamics in automotive projects. Additionally, these bespoke pieces can be designed to match aesthetic preferences. However, customization can lead to increased costs and longer lead times. It’s crucial to balance these factors against the project’s goals.

Another important aspect to consider is the potential for innovation. Custom fabrication can lead to creative designs not possible with standard options. This is where industries can push boundaries. While there may be challenges, the rewards often outweigh the risks. Embracing bespoke metal fabrication can open doors to distinctive solutions that stand out.

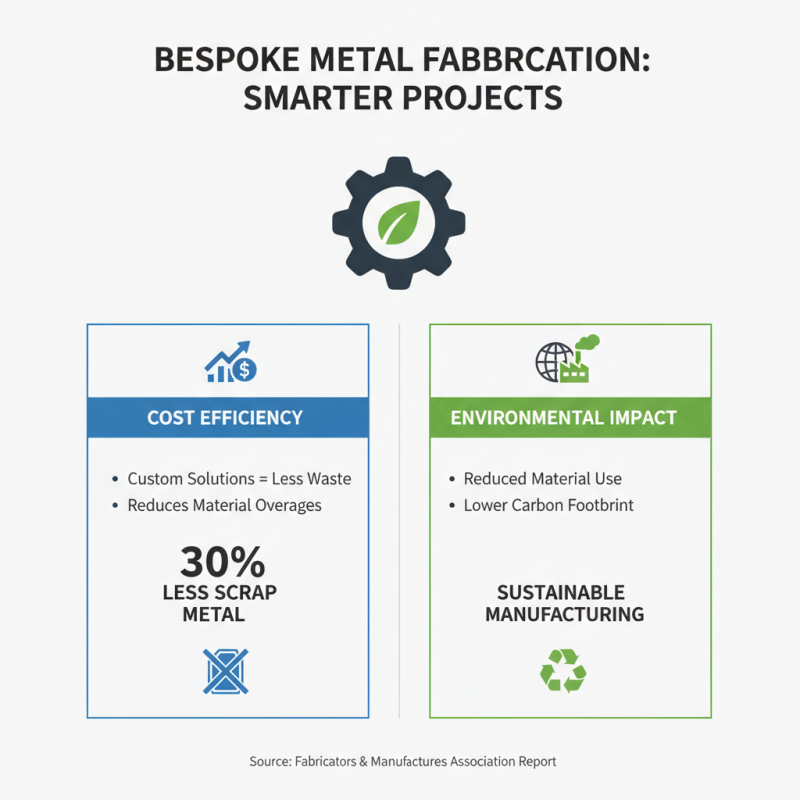

Cost Efficiency: How Bespoke Solutions Reduce Waste and Improve Value

Bespoke metal fabrication presents significant cost efficiency for construction and manufacturing projects. Custom solutions are designed to fit specific needs, reducing waste associated with mass production. According to a recent report by the Fabricators and Manufacturers Association, 30% of materials in traditional production can end up as scrap. This not only raises costs but also generates unnecessary environmental impact.

When projects use bespoke metal fabrication, waste is minimized. A tailored approach ensures that materials are cut and shaped precisely, without excess. Research indicates that companies adopting custom fabrication can save up to 20% on material costs. This is crucial, as rising raw material prices demand a more judicious approach. However, switching to bespoke solutions is not without challenges. Companies must invest in skilled labor and advanced technology, which can lead to initial costs.

Moreover, while bespoke solutions streamline production, they may sometimes require longer lead times. This delay can be a point of frustration for project managers. Balancing time and cost-efficiency remains a tightrope walk for many businesses. Ultimately, the potential for waste reduction and value improvement makes bespoke metal fabrication an attractive option, despite the hurdles involved.

Quality Assurance: The Role of Precision in Metal Fabrication

Precision plays a significant role in bespoke metal fabrication. When projects demand high-quality results, attention to detail is non-negotiable. Metal parts must fit seamlessly and function flawlessly. Precision ensures that components perform as intended without any unnecessary adjustments.

For successful fabrication, one must focus on the specifics. Choose the right materials based on the project's needs. This dictates how components will respond under stress or wear. It’s important to consult with professionals who understand these requirements. Ensure your designs are not overly complicated. Simple designs often yield better results.

Tip: Always verify tolerances during the design phase. Specify what you need clearly to avoid miscommunication. Regularly review prototypes to identify potential issues early on. Feedback is crucial. Adaptability should be embraced. If something isn’t working, reflect on why and make necessary adjustments. Flexibility in the design process can lead to innovative solutions.

Material Selection: Tailoring Metals to Enhance Performance Attributes

Material selection is crucial in bespoke metal fabrication. Different projects demand specific metal attributes. Customizing materials can enhance durability, weight, and corrosion resistance. For example, choosing aluminum over steel can reduce weight for aerospace applications. Specialized alloys can offer improved strength in demanding conditions.

Tailoring metals can lead to unexpected challenges. Not every metal behaves as anticipated during fabrication. Some materials may warp or behave unpredictably under stress. It’s essential to understand these nuances. A well-informed choice can prevent costly mistakes down the line. Sometimes, experimenting with less common materials may lead to superior outcomes, but this requires careful testing.

Involving skilled artisans can make a difference. Their experience with various metals can uncover options you might not consider. They can provide insights on working properties and long-term performance. It’s all about finding the right balance. The ideal metal might not be the obvious choice at first glance. A thoughtful approach can yield remarkable results, even when the initial selection process feels daunting.

Top 10 Benefits of Bespoke Metal Fabrication for Your Projects

| Benefit | Description | Performance Attributes | Ideal Metals |

|---|---|---|---|

| Customization | Design components specifically tailored to project needs. | Enhanced functionality and fit. | Aluminum, Steel |

| Quality Control | Rigorous quality checks ensure high standards. | Durability, reliability. | Stainless Steel |

| Cost Efficiency | Reduced waste through precise designs. | Lower overall material costs. | Mild Steel, Copper |

| Speed | Faster production times with bespoke processes. | Quicker project turnover. | Aluminum, Titanium |

| Material Variety | Access to a wide range of metals for diverse needs. | Versatile applications. | Bronze, Nickel |

| Precision Engineering | Highly accurate fabrication processes. | Increased performance accuracy. | Titanium, Alloy Steel |

| Sustainability | Eco-friendly metal options available. | Reduced environmental impact. | Recycled Aluminum |

| Innovative Solutions | Creative designs utilizing advanced technologies. | Enhanced performance capabilities. | Composite Materials |

| Expertise | Skilled professionals ensure high-quality results. | Optimized designs. | Specialty Alloys |

| Aesthetic Appeal | Custom finishes enhance visual impact. | Improved branding potential. | Anodized Aluminum, Painted Steel |

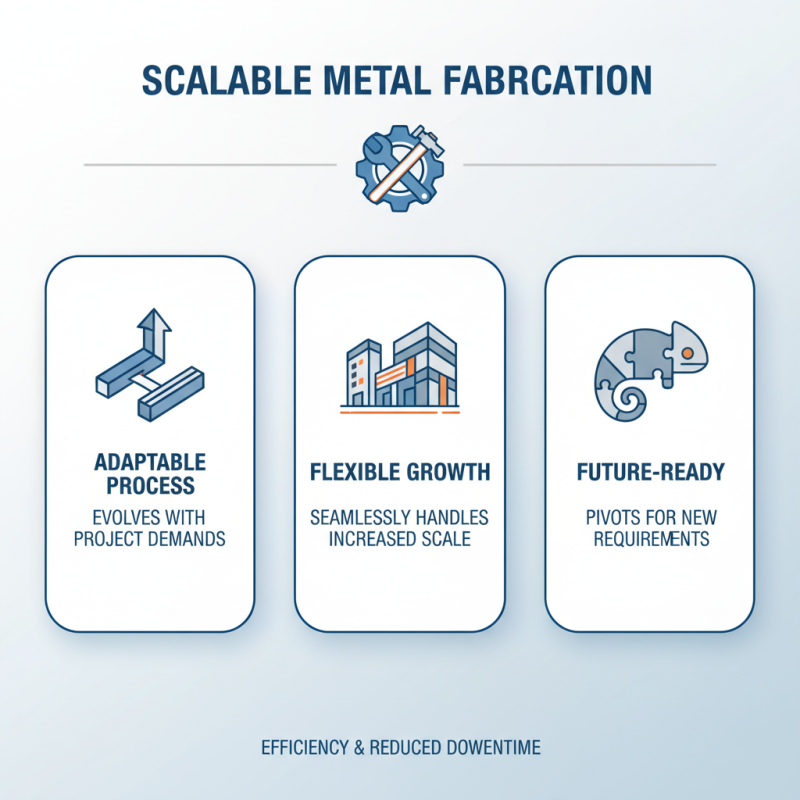

Scalability: Adapting Fabrication Techniques for Project Expansion

When it comes to bespoke metal fabrication, scalability is a crucial advantage. Custom fabrication methods can evolve alongside project demands. This flexibility ensures that as project scales increase, the fabrication process can adapt seamlessly. Crafting unique parts today may lead to entirely new requirements tomorrow. This ability to pivot enhances efficiency and reduces downtime.

Consider a project that starts small but gains traction. It is vital for the fabrication team to respond quickly. A sudden influx of orders often brings unique challenges. The ability to modify designs and production rates becomes essential. A skilled team can quickly adjust without sacrificing quality. The process must remain smooth, even in the face of unexpected shifts.

However, scaling isn't without its challenges. Sometimes, increased demand leads to rushed work and mistakes. Plans must be laid out carefully to prevent errors. Teams may need to reflect on previous projects to improve future scalability. Learning from missteps helps in developing robust strategies for expansion. Emphasizing these practices ensures that bespoke fabrication meets evolving project needs effectively.

Related Posts

-

2026 Top Trends in Custom Metal Fabrication You Need to Know

-

Top 10 Tips for Successful Online Sheet Metal Fabrication Projects

-

Top Custom Steel Fabrication Trends to Watch in 2025: What You Need to Know

-

2025 Top Trends in Precision Sheet Metal Fabrication You Need to Know

-

How to Choose Custom Metal Fabrication Services for Your Project?

-

Top Tips for China Sheet Metal Fabrication Success?