Projects

2025 Top Trends in Precision Sheet Metal Fabrication You Need to Know

As we approach 2025, the field of precision sheet metal fabrication is set to witness transformative changes that will redefine industry standards and operational efficiency. Recent reports suggest that the global sheet metal fabrication market is anticipated to grow significantly, with a compound annual growth rate (CAGR) of approximately 5.5% from 2022 to 2027. This growth is driven by an increasing demand for customized metal products across diverse sectors, including automotive, aerospace, and electronics, which rely heavily on precision engineering.

The advancements in precision sheet metal fabrication technology, such as automated laser cutting and 3D modeling, are streamlining production processes and enhancing quality control. Additionally, the integration of Industry 4.0 principles, including IoT and smart manufacturing, is enabling companies to achieve greater precision and consistency in their fabrication processes. As the industry evolves, staying informed about these top trends will equip manufacturers and stakeholders with the knowledge needed to adapt and thrive in a competitive landscape. Emphasizing the importance of precision sheet metal fabrication, collaborative innovations amongst industry players and technological advancements are key to meeting the growing demands for high-quality, efficient, and sustainable manufacturing solutions.

Emerging Technologies Driving Precision Sheet Metal Fabrication: 2025 Insights

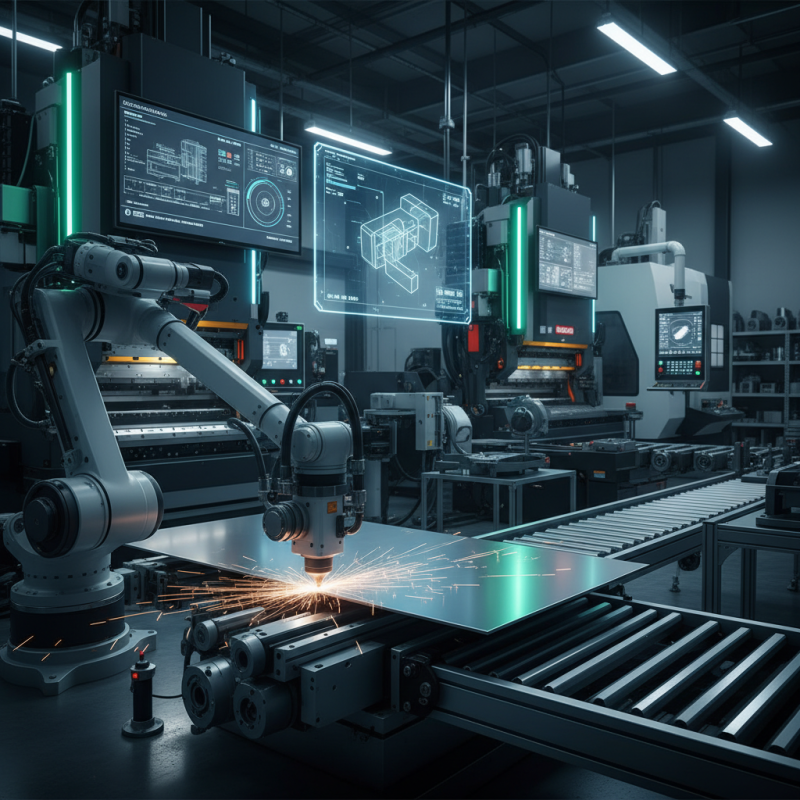

The landscape of precision sheet metal fabrication is rapidly evolving, driven by emerging technologies that promise to transform the industry by 2025. One key trend is the integration of advanced automation and robotic systems, which enhance efficiency and precision in manufacturing processes. These technologies reduce human error and improve turnaround times, allowing manufacturers to respond quickly to market demands. Additionally, the use of AI and machine learning in production planning and quality control is becoming increasingly prevalent, optimizing workflows and minimizing material waste.

Another significant development is the rise of additive manufacturing techniques, which complement traditional subtractive methods. By allowing for complex geometries and lightweight structures, 3D printing enables designers to push the boundaries of what can be achieved in sheet metal fabrication. This synergy between additive and subtractive processes offers unprecedented flexibility, enabling manufacturers to innovate in product design and customization. Furthermore, advancements in materials science, such as the development of new alloys and surface treatments, contribute to enhanced durability and performance of fabricated components, setting the stage for more sustainable practices in the industry.

Key Industry Trends Impacting Precision Sheet Metal Fabrication in 2025

In 2025, the landscape of precision sheet metal fabrication is poised for transformative changes driven by advancements in technology and evolving industry demands. One key trend is the increasing integration of automation and robotics in the fabrication process. This shift not only boosts efficiency but also significantly enhances precision in manufacturing. Companies are investing in smart technologies that enable real-time monitoring and adjustments, leading to improved product consistency and reduced material waste.

As businesses adapt to these technological advancements, a notable emphasis on sustainability will emerge as another critical trend. Fabricators are exploring eco-friendly materials and energy-efficient processes to reduce their carbon footprint and comply with stricter environmental regulations. This shift towards sustainable practices not only appeals to environmentally conscious customers but also opens new avenues for innovation in product design and manufacturing techniques.

Tips: To stay ahead in this evolving industry, fabricators should invest in training programs for employees to familiarize them with new technologies. Collaboration with technology providers can also enhance the adoption of advanced solutions. Furthermore, keeping abreast of sustainable practices and certifications will not only improve competitiveness but also align with global sustainability goals. Embracing these changes is essential for thriving in the rapidly changing world of precision sheet metal fabrication.

2025 Trends in Precision Sheet Metal Fabrication

This chart illustrates the anticipated impact of key trends in precision sheet metal fabrication by 2025. Automation adoption is expected to have the highest impact, followed by sustainability initiatives and advanced materials.

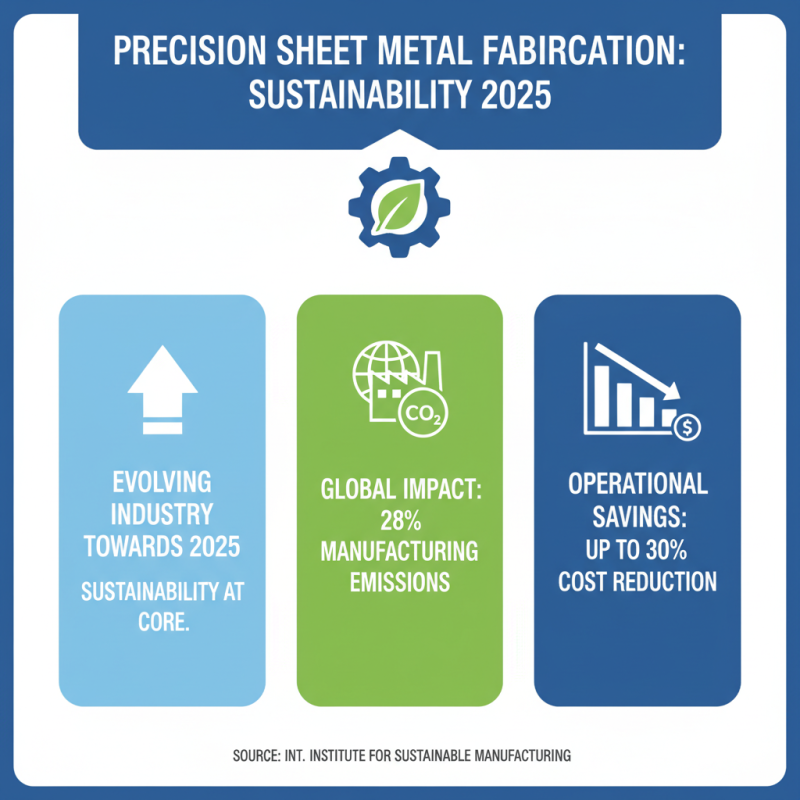

Sustainability Practices in Precision Sheet Metal Fabrication: A Growing Focus

As the precision sheet metal fabrication industry evolves toward 2025, sustainability practices are increasingly taking center stage. With the manufacturing sector responsible for approximately 28% of global carbon emissions, companies are under mounting pressure to adopt more environmentally friendly practices. A recent report by the International Institute for Sustainable Manufacturing indicates that firms integrating sustainable approaches can reduce operational costs by up to 30%, illustrating the financial benefits of going green alongside the environmental imperative.

Key strategies include optimizing material usage and minimizing waste through advanced computer-aided design (CAD) and manufacturing processes. By implementing techniques such as nesting and using recyclable materials, manufacturers can significantly decrease scrap rates. The 2022 Metal Fabrication Sustainability Survey highlighted that 65% of surveyed companies are investing in technologies aimed at reducing waste and improving energy efficiency, a trend set to rise as regulatory standards tighten and consumer preferences shift towards greener products. Furthermore, the integration of renewable energy sources in fabrication facilities not only aligns with sustainability goals but also enhances brand reputation and market competitiveness.

In addition, the circular economy is gaining traction in precision sheet metal fabrication. Emphasizing reusability and recyclability, this approach encourages manufacturers to rethink their processes and product lifecycles. By fostering partnerships with recycling organizations and developing take-back programs, companies can contribute to a more sustainable industry overall. With stakes high, the alignment of sustainability practices in precision sheet metal fabrication is not just beneficial; it's becoming essential for long-term success and adaptability in the marketplace.

The Role of Automation and Robotics in Shaping Future Fabrication Methods

The role of automation and robotics in precision sheet metal fabrication is becoming increasingly significant as manufacturers strive for greater efficiency and accuracy. Automation technologies streamline production processes, reducing manual labor and minimizing human error. This shift allows companies to achieve higher output rates while maintaining consistent quality. Robotics, in particular, enhance capabilities by performing complex tasks such as laser cutting, welding, and bending with precision that exceeds human hands.

For those looking to implement automation in their fabrication processes, here are a couple of tips: first, assess your current workflow to identify areas where automation can provide immediate benefits, such as repetitive tasks or processes prone to errors. Second, invest in training for your workforce to adapt to new technologies, ensuring they can collaborate effectively with automated systems. This will not only enhance productivity but also empower your team to embrace the advantages that come with innovation.

As technology advances, the integration of automation and robotics will likely redefine the landscape of precision sheet metal fabrication. Companies that proactively adopt these trends will find themselves at the forefront of the industry, equipped to meet the increasing demands for high-quality, cost-effective solutions. Embracing these changes today is essential for staying competitive in the future.

2025 Top Trends in Precision Sheet Metal Fabrication You Need to Know

| Trend | Description | Impact Level | Implementation Year |

|---|---|---|---|

| Automation in Cutting Processes | Integration of automated cutting machines for faster and more precise operations. | High | 2025 |

| Robotics in Welding | Use of robotic arms to enhance welding precision and reduce human error. | Medium | 2025 |

| AI-Powered Design | Artificial Intelligence tools for optimizing designs for manufacturability. | High | 2025 |

| IoT Integration | Utilization of IoT devices for real-time monitoring of equipment and processes. | Medium | 2025 |

| Sustainable Practices | Adoption of eco-friendly materials and processes in sheet metal fabrication. | High | 2025 |

Customization and On-Demand Production: Meeting the Needs of Modern Industries

The landscape of precision sheet metal fabrication is rapidly evolving, driven by the demand for customization and on-demand production. Modern industries require tailored solutions that address specific needs, leading to increased flexibility in design and manufacturing processes. The ability to produce unique components quickly not only enhances product quality but also accelerates time-to-market, which is essential in today's competitive environment. As manufacturers embrace innovative technologies, they can create bespoke solutions that cater directly to client specifications, making customization a cornerstone of fabrication strategies.

To effectively implement customization in your fabrication processes, consider the following tips:

First, invest in advanced manufacturing technologies such as laser cutting and 3D printing that allow for rapid prototyping and modifications without significant downtime. This flexibility enables easier adjustments to designs, accommodating any change in client requirements.

Second, prioritize communication with clients. Clear and continuous dialogue ensures that their vision is accurately translated into production, resulting in fewer revisions and increased satisfaction.

Moreover, leveraging on-demand production can significantly optimize resource management. By producing only what is necessary, manufacturers can reduce waste and inventory costs. Establishing a streamlined workflow that can jump from design to production with minimal delays will enhance responsiveness to market demands. Emphasizing these aspects of customization and on-demand production will position your business to meet contemporary industry challenges effectively.

Related Posts

-

Top 5 Online Steel Fabrication Services You Need to Know in 2023

-

Top 10 Tips for Successful Online Sheet Metal Fabrication Projects

-

Top 10 Tips for Low Cost Sheet Metal Fabrication to Save Your Budget

-

What is Tube Fabrication and How Does it Impact Manufacturing Processes

-

How to Get Started with Welding and Fabrication Techniques for Beginners

-

Top Custom Steel Fabrication Trends to Watch in 2025: What You Need to Know